While I was waiting for some things to dry and some other things to print, I took a crack at modeling up the back fixture to connect the hose and the airbag together. I did do some digging to see if I could find a reasonable plumbing fitting, and there were some options, but at this point I kinda like the idea of trying to print it just to see if I can, so…

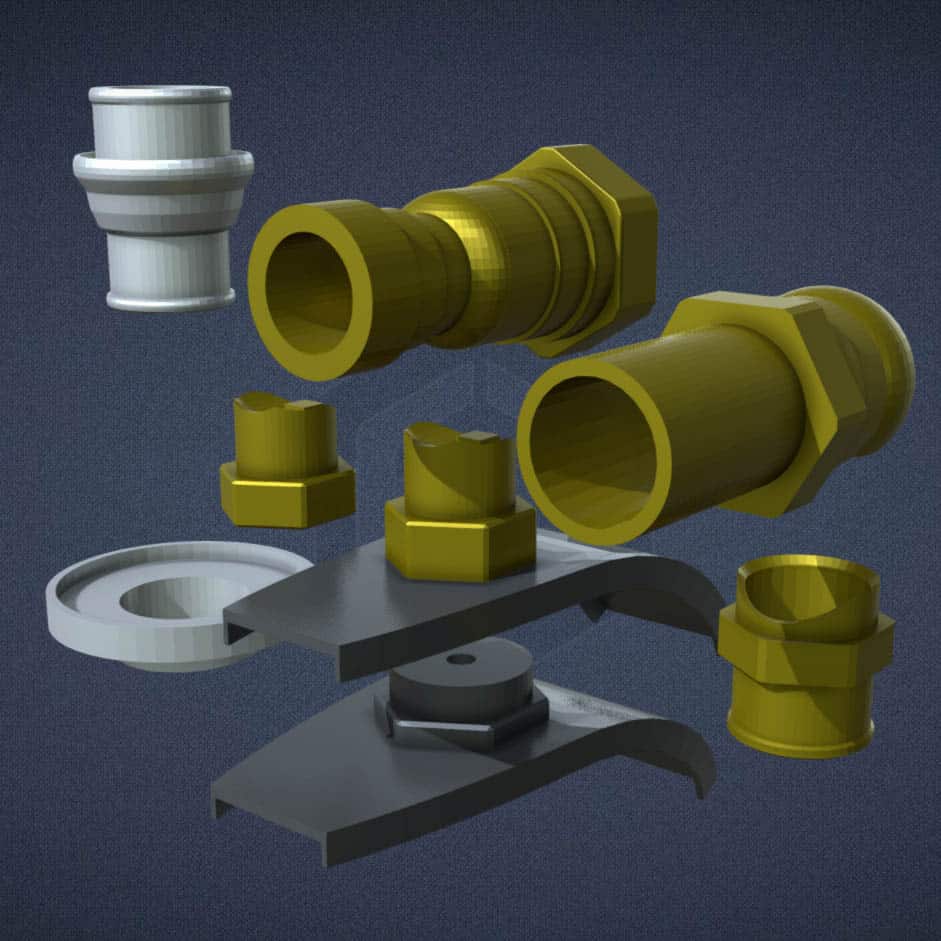

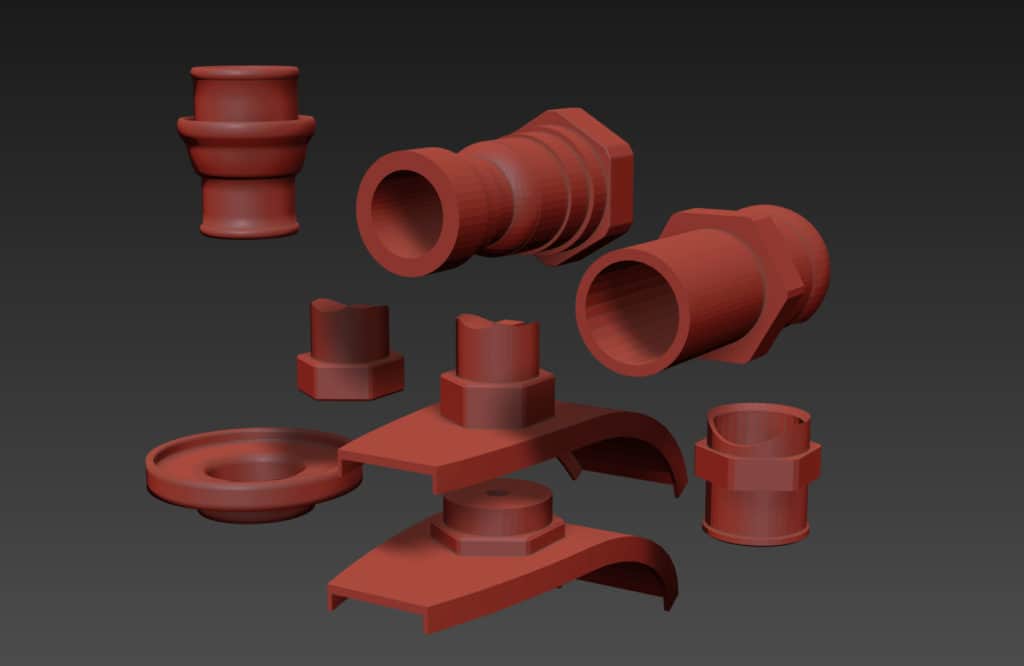

This was what I came up with. The top of the pipe is fitted with a flared bit that I should be able to snugly fit the end of the black gas mask hose around. The left end of the pipe will stick in through a metal L-bracket that mounts onto the armor or airbag itself – it looks like part of that whole assembly – and the tube will snug into some flexible tubing I have in mind for inside the airbag that will lead to the fan. I swept a smooth curve inside the fixture that’s about 23mm in diameter which should keep the air moving relatively smoothly.

It was also modeled to come apart as two separate pieces to make the printing of it easier. Vertical curves and right angles that stick out into space are the enemy of a FDM printer, so this should minimize the amount of weirdness that the printer produces. It’ll still need supports, but if I get everything right, I should be able to glue these parts snugly together, then coat the inside with a thin layer of resin or maybe even XTC-3D to ensure that the join is smooth and consistent.

Unfortunately, I won’t be able to get these printing until tomorrow morning, as right now my machine is tied up with these fittings, instead.

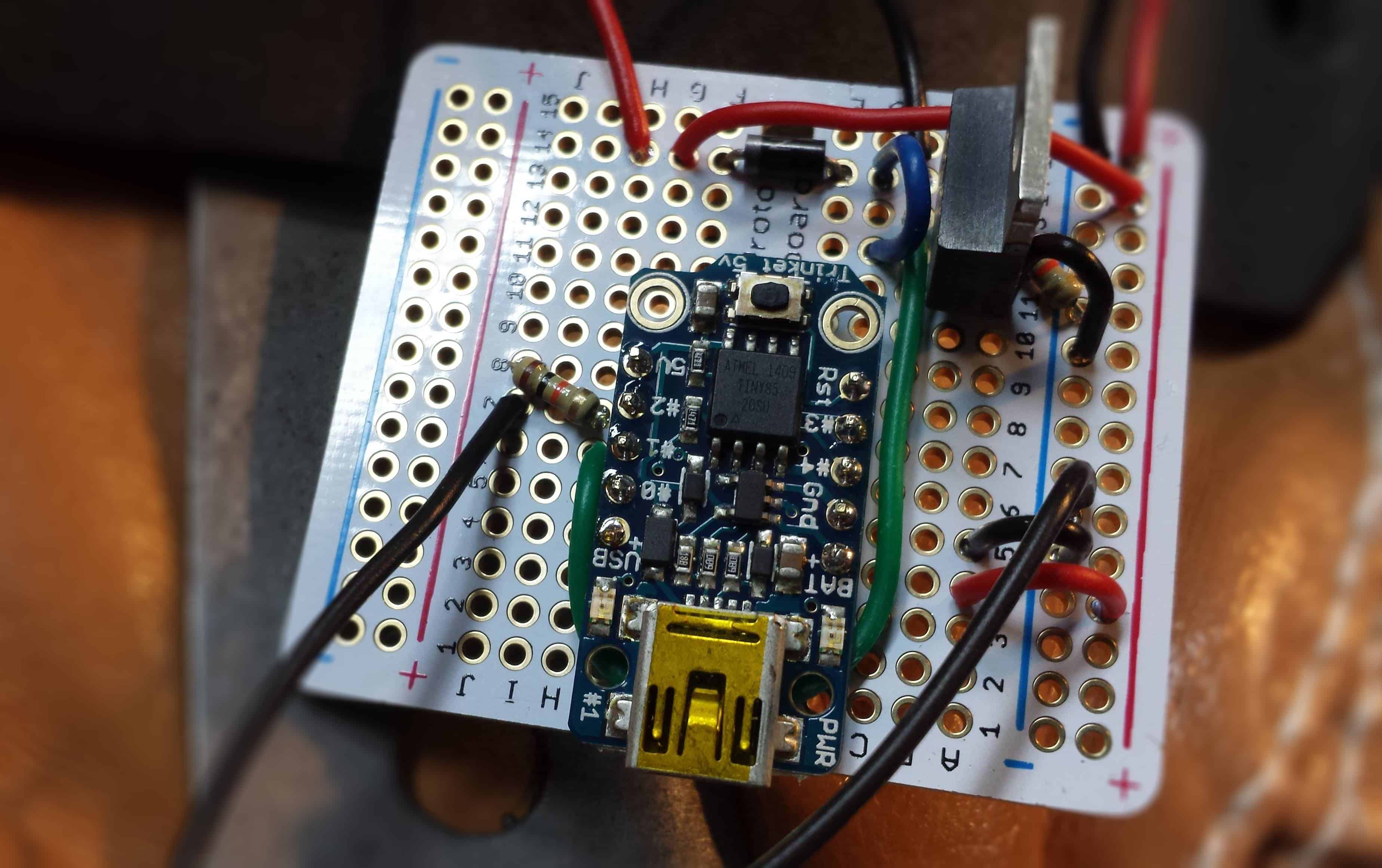

These little suckers are designed to bolt straight onto my 40mm high-CFM fans on one end and the back end of that white flexible corrugated tube in my last post on the other end. Should give me a good seal, but I’ll be able to try it out tomorrow morning. My end goal here is to get all of the hardware assembled and inline so I have the fan sucking in the air through all the fixtures at one end and blowing out through all the length of hose that will be necessary at the other, so I can confirm that the little fan I bought has the horsepower to actually move that much static pressure. We’ll see!