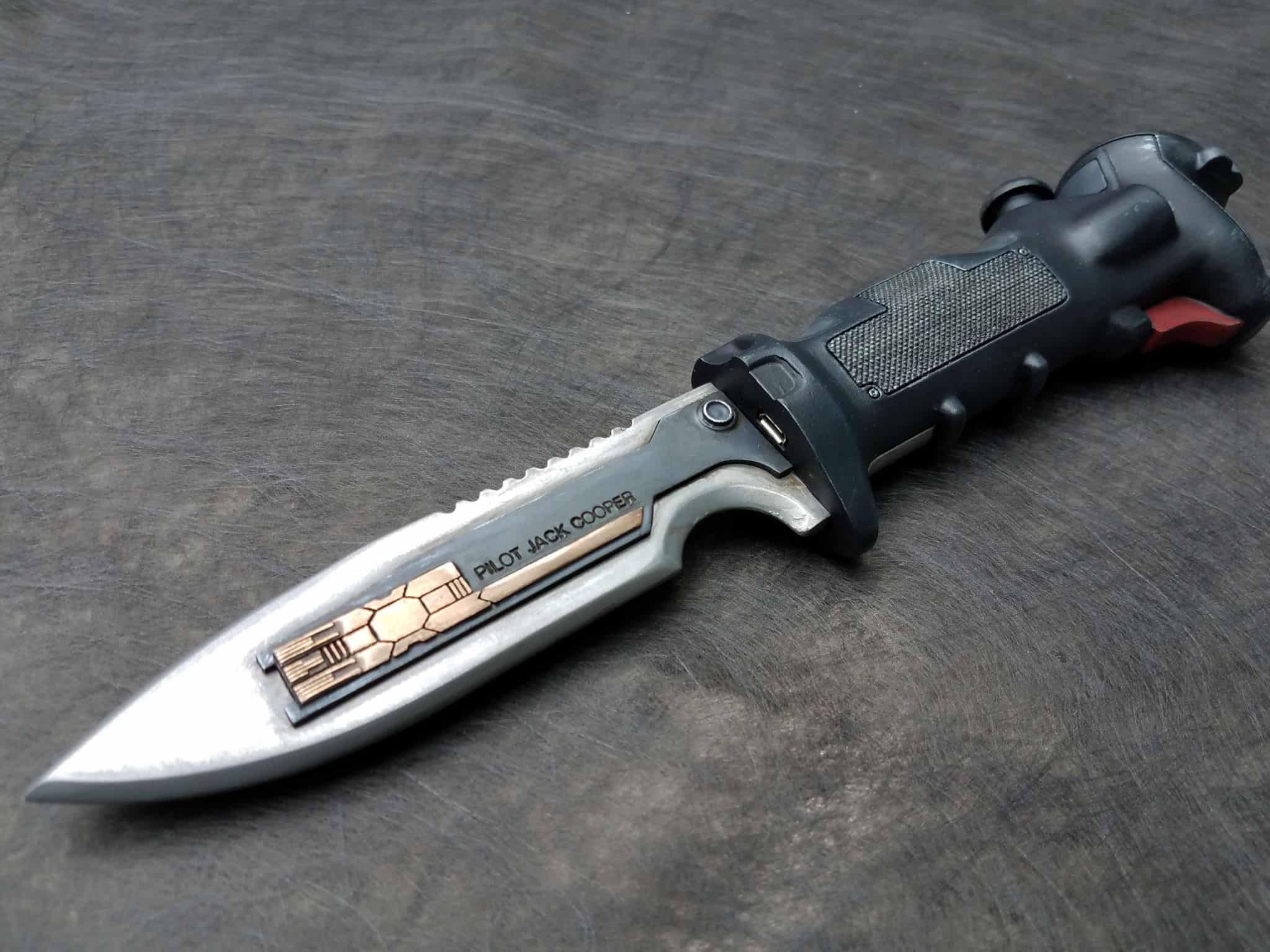

So I got the data knife printed out pretty much in entirety and have noticed some things I wanted to address. Pictures first, though!

It is just loosely held together by two screws in the battery compartment cover at the moment and the friction fitting of the blade into the handle. What I noticed was that the 5x5mm LED holes I built into the handle to backlight the ‘screen’ did not print as nicely as I wanted, which should be pretty evident based on the above images. I could absolutely just drill these things out and make them work properly, buuuuut… this morning, I discovered a better alternative.

Adafruit apparently makes the “NeoPixel Jewel“, which is the size of a U.S. quarter and has 7 RGBW LEDs already arranged in a nice disc shape with easy solder points and the data wiring and smoothing capacitors already built in.

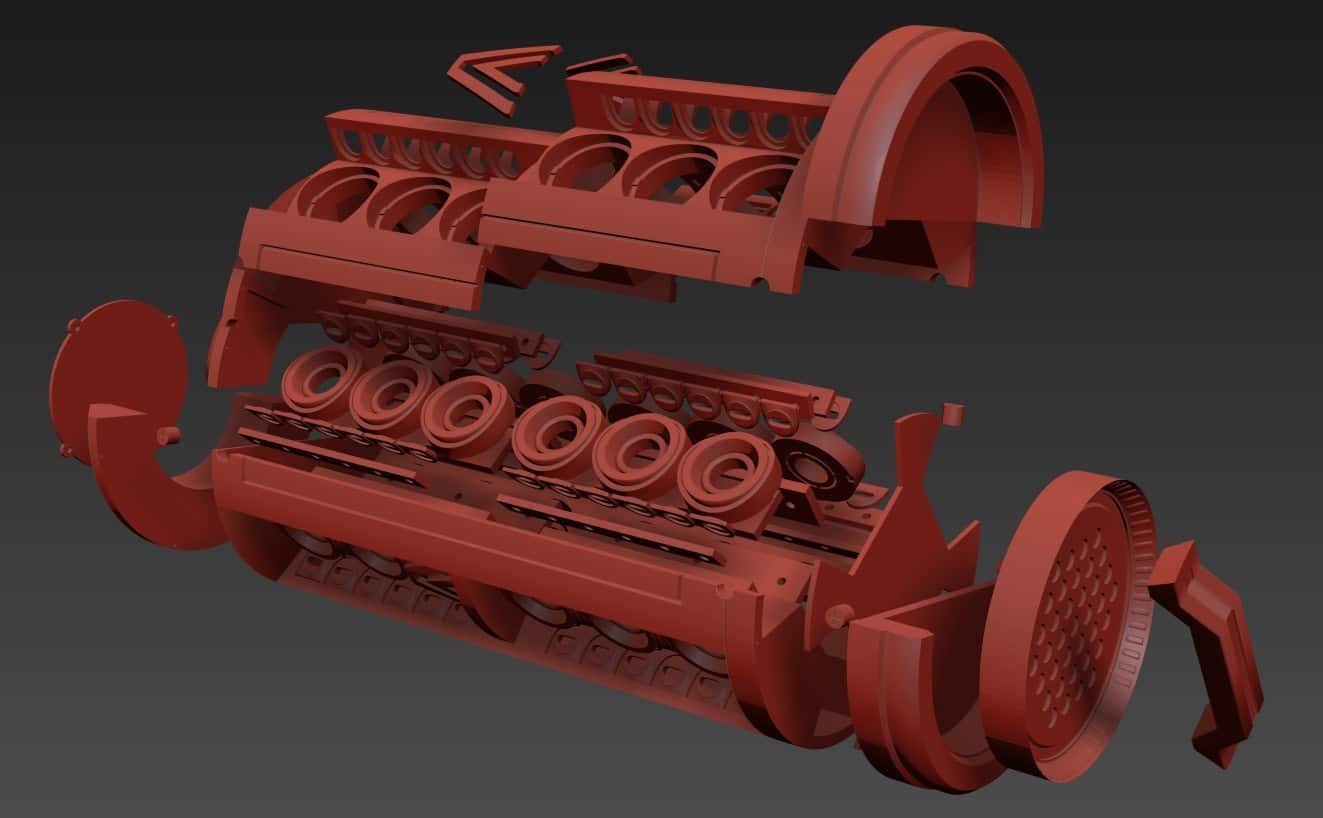

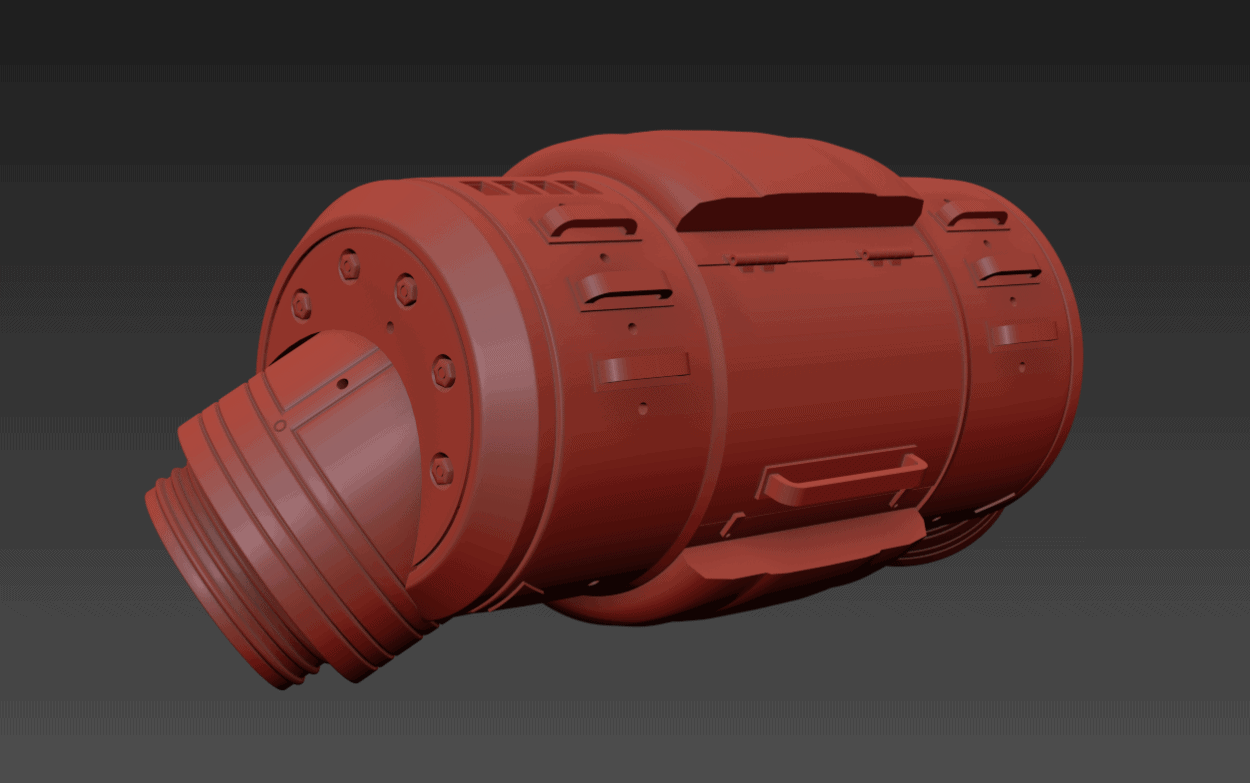

Hard to beat that, to be honest, and it saves me the trouble of trying to do a lot of fiddly wiring. I just bought one today, and immediately set about redesigning the handle to accommodate one:

Should ultimately be a lot simpler to print, too.

While I was at it, I also redesigned the bezel around the top of the display ring. The laser-cut discs I have ended up being just a little too small and had about 1mm of room around all sides when inserted into the handle. The new bezel should hopefully tighten that fit up nicely. I may have misjudged exactly how wide the cutting beam for the laser was!

I’ve got the handle re-printing now, but I figure I’ll use this data knife I’ve already got printed as a spare to test paint and other options with. Once I confirm everything fits the way it should, I’ll release the files for the full electronics data knife setup for anyone who might want to try making their own.